Thermoplastic Elastomer (TPE) and its Properties

Share on facebook Share on linkedin Share on whatsapp Share on telegram Share on email What is TPE? Thermoplastic elastomer is a type of thermoplastic polymer. They are a physical

Southeast Asia is one of the biggest market for latex applications as the region has abundant resources to produce rubber, especially in Thailand, Malaysia, and Indonesia. As MahaChem has seen the industry as the big opportunity, MahaChem has worked closely with several big manufacturers in the latex application suppliers.

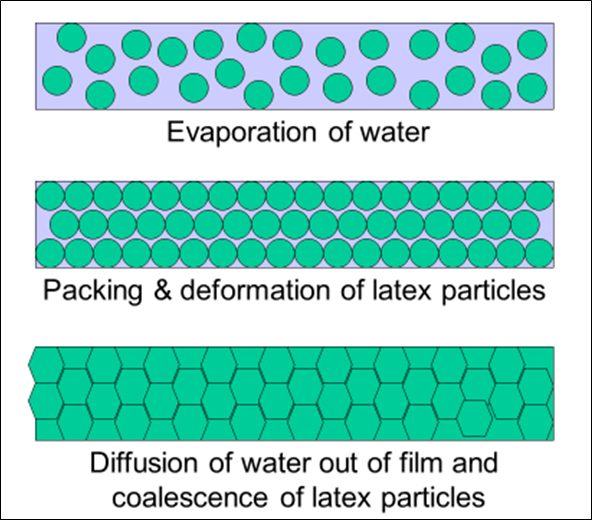

The film formation process of latex film involves mainly three steps :

However, in this process, Minimum Film Forming Temperature (MFFT) is very crucial.

The MFFT indicates the temperature required for the latex to from a film. MFFT can be found in the technical data sheets of latex products.

If the MFFT of the latex is lower than the room temperature, it can form a smooth and continuous film at room temperature.

If the MFFT of latex is higher than the room temperature, the latex will not form a continuous film. It will form a cracked film.

What should one do in such case?

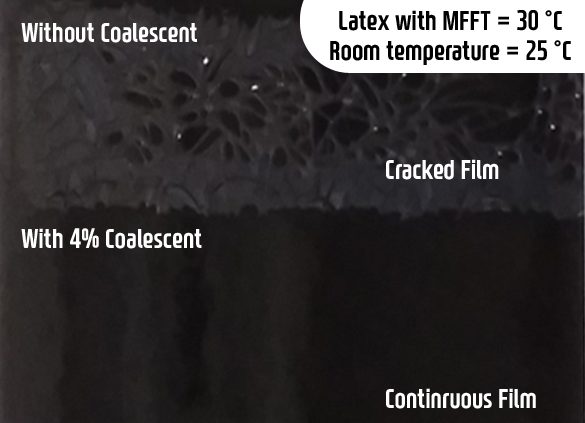

In this case, coalescing solvent is required to soften the latex particles so that they can coalesced to form a continuous film.

The below image shows a side by side drawdown of two latex films at room temperature. The MFFT of the latex is 30 °C and the room temperature is 25 °C. The latex film without coalescent has cracked. The latex film with 4% coalescent formed a continuous film. The amount of coalescent used is calculated based on latex solids.

MahaChem is distributing two brands of coalescing solvent, Maha Coalescent CS-12 and Maha Coalescing Solvent. The performance of both grades are equivalent to Texanol of Eastman Chemicals.

Share on facebook Share on linkedin Share on whatsapp Share on telegram Share on email What is TPE? Thermoplastic elastomer is a type of thermoplastic polymer. They are a physical

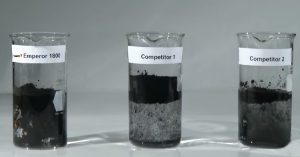

Do you still find it difficult to adopt carbon black due to dispersibility issue? We introduce you EMPEROR Carbon Black Grades to solve your problem. Find out more from here.

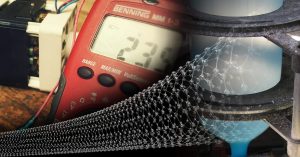

Anti-static polymers have been seen as an increasing requirement in the coming years, but commonly used additives in the plastic industries are generally non-permanent. How to solve this?

Copyright © 2023 Maha Chemicals (Asia) Pte Ltd