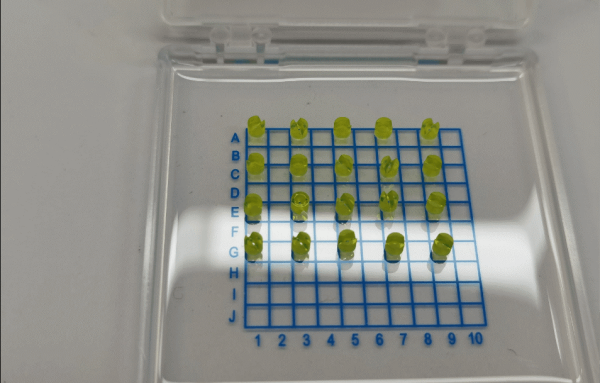

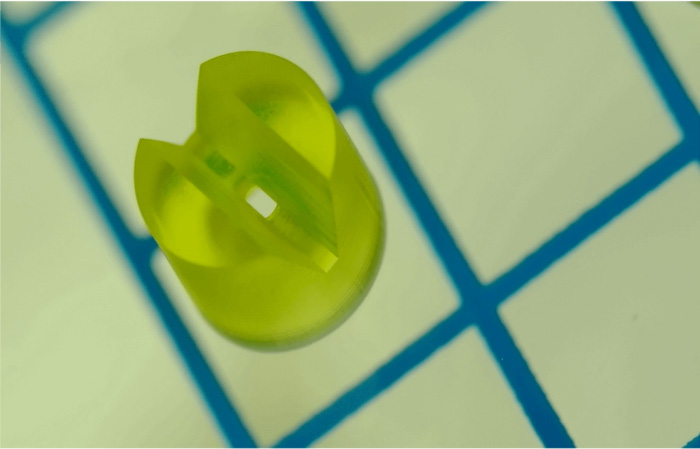

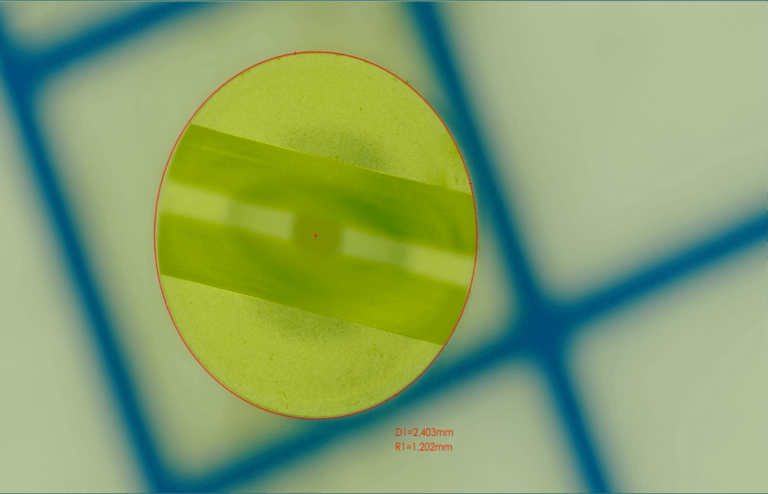

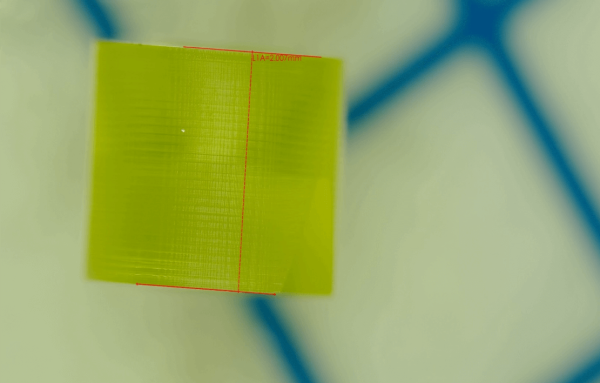

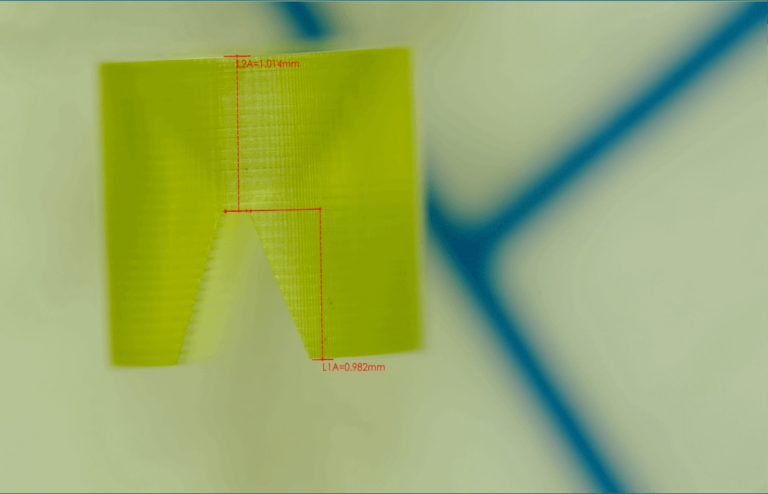

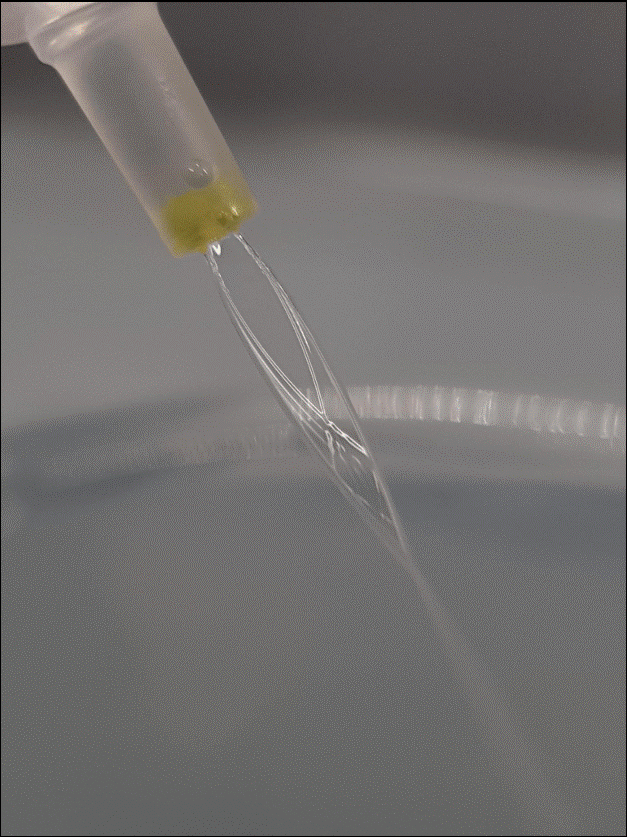

Advances PμSL Technology Solutions For Effective Keratitis Treatment

Keratitis is an iflammation of the cornea, mainly caused by injury, bacteria and viruses. Keratitis can be divided into two categories: non-infectious and infectious, the latter can lead to serious